- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Cylindrical Gear

20CrMnTi; 40Cr; 42CrMo; C40; SAE8620H

Hobbing & shaving & grinding

Transmission

Carburizing

Transmission Double Gear Teeth Shaping Gear Transmission Double Gear Teeth Shaping GearSpur gears are cylindrical gears with straight teeth cutted around the circumference and the teeth is parallel with the inner shaft. Spur gears are very common in many kinds of transmission fields, such as truck transmission, industrial gear reducer, agricultural machinery, wind power etc. Spur gears are much easier to produce compared with other kinds of gears, such as bevel gears and helical gears. Nowadays, hobbing, shaving, shaping, broaching and grinding are mostly applied in the production of helical gears. And for spur gears, we can supply: 1. Material: 20CrMnTi, 42CrMo, Stainless Steel, Brass, Plastic, Nylon, Aluminium, etc. |

Production Characteristics

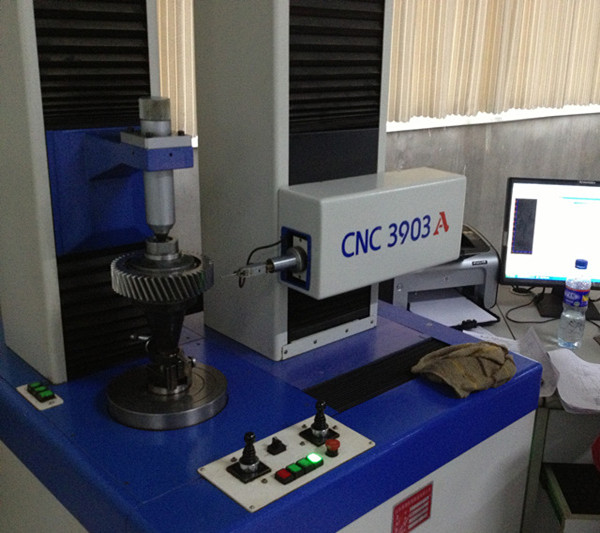

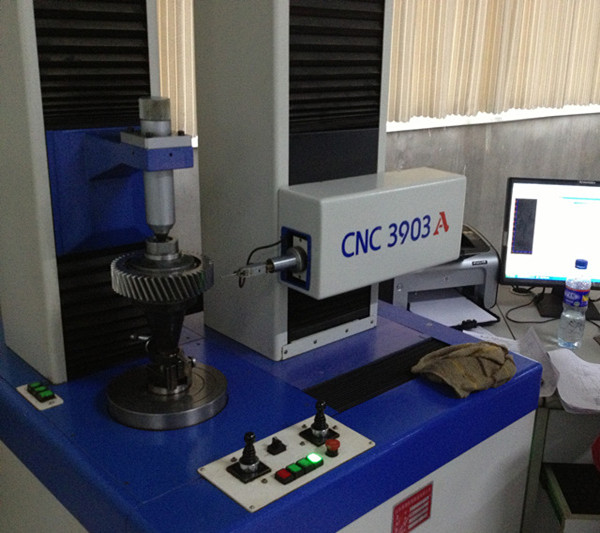

Teeth Profile Inspection |  High Speed Hobbing |  Auto Production Line |

Specifications & Capabilities

| Gear Type | Material | Heat Treatment | Process | Grade | MAX O.D./mm | Module/mm |

| Spur&Helical Gear | 20CrMnTi,C40,C45, 40Cr,42CrMo, Aluminium Alloy, Stailess Steel 304/316, SAE8620H | Carburizing,Nitriding, Quenching&Tempering, Induction Hardening, Normalizing | Hobbing | DIN8 | 200 | 1-32 |

| Shaving | DIN7 | 200 | 1-8 | |||

| Shaping | DIN8 | 400 | 1-7 | |||

| Broacing | DIN7 | 400 | 1-7 | |||

| Grinding | DIN5 | 300 | 1-7 | |||

| Straight bevel Gear | Precision Forging | DIN8 | 200 | 1.5-10 | ||

| Cold Extrusion | DIN8 | 90 | 1.5-6 | |||

| Cutting | DIN8 | 300 | 1.5-10 | |||

| Spiral Bevel Gear | Milling | DIN7 | 600 | 1-15 | ||

| Grinding | DIN5 | 300 | ||||

| Spline Shaft | Hobbing | DIN8 | L600 | 0.5-2 | ||

| Grinding | DIN5 | L260 |

Production Flow

Plant Gallery

Transmission Double Gear Teeth Shaping Gear Transmission Double Gear Teeth Shaping GearSpur gears are cylindrical gears with straight teeth cutted around the circumference and the teeth is parallel with the inner shaft. Spur gears are very common in many kinds of transmission fields, such as truck transmission, industrial gear reducer, agricultural machinery, wind power etc. Spur gears are much easier to produce compared with other kinds of gears, such as bevel gears and helical gears. Nowadays, hobbing, shaving, shaping, broaching and grinding are mostly applied in the production of helical gears. And for spur gears, we can supply: 1. Material: 20CrMnTi, 42CrMo, Stainless Steel, Brass, Plastic, Nylon, Aluminium, etc. |

Production Characteristics

Teeth Profile Inspection |  High Speed Hobbing |  Auto Production Line |

Specifications & Capabilities

| Gear Type | Material | Heat Treatment | Process | Grade | MAX O.D./mm | Module/mm |

| Spur&Helical Gear | 20CrMnTi,C40,C45, 40Cr,42CrMo, Aluminium Alloy, Stailess Steel 304/316, SAE8620H | Carburizing,Nitriding, Quenching&Tempering, Induction Hardening, Normalizing | Hobbing | DIN8 | 200 | 1-32 |

| Shaving | DIN7 | 200 | 1-8 | |||

| Shaping | DIN8 | 400 | 1-7 | |||

| Broacing | DIN7 | 400 | 1-7 | |||

| Grinding | DIN5 | 300 | 1-7 | |||

| Straight bevel Gear | Precision Forging | DIN8 | 200 | 1.5-10 | ||

| Cold Extrusion | DIN8 | 90 | 1.5-6 | |||

| Cutting | DIN8 | 300 | 1.5-10 | |||

| Spiral Bevel Gear | Milling | DIN7 | 600 | 1-15 | ||

| Grinding | DIN5 | 300 | ||||

| Spline Shaft | Hobbing | DIN8 | L600 | 0.5-2 | ||

| Grinding | DIN5 | L260 |

Production Flow

Plant Gallery

Home | About Us | Products | Production | Application | News | Contact Us